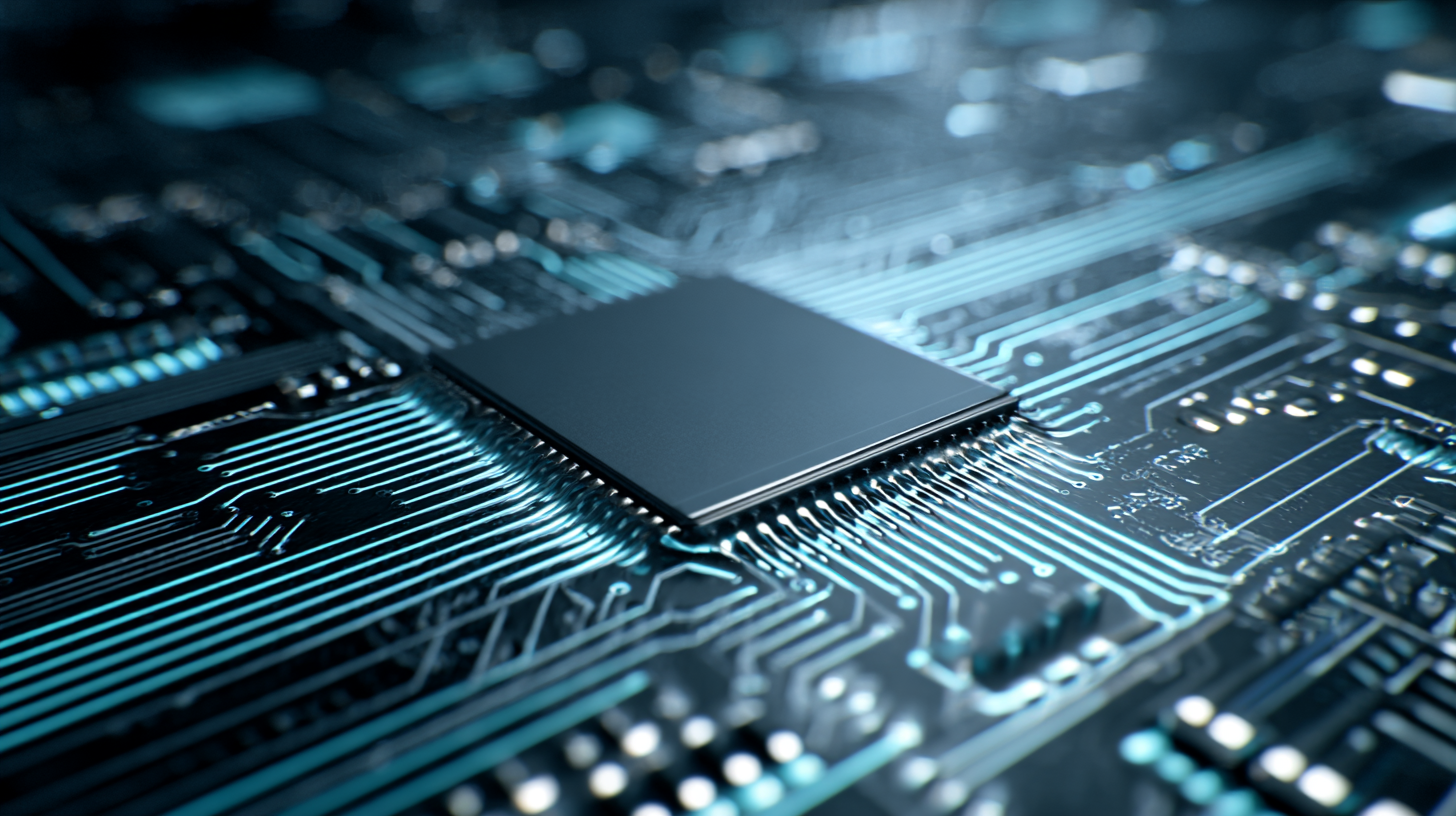

The advent of the Ceramic Semiconductor marks a significant milestone in the evolution of technology, offering unique advantages over traditional semiconductor materials. According to a recent report by MarketsandMarkets, the global semiconductor market is projected to grow from USD 527.2 billion in 2021 to USD 726.73 billion by 2026, driven by emerging innovations like Ceramic Semiconductors. These materials boast enhanced temperature stability and improved electrical performance, making them ideal for a wide range of applications, including power electronics and high-frequency circuits. Their lightweight and compact nature further contributes to the miniaturization trends observed in modern electronics. As industries increasingly seek efficient and sustainable solutions, the integration of Ceramic Semiconductors is set to redefine performance standards and open new avenues for technological advancement.

The advent of the Ceramic Semiconductor marks a significant milestone in the evolution of technology, offering unique advantages over traditional semiconductor materials. According to a recent report by MarketsandMarkets, the global semiconductor market is projected to grow from USD 527.2 billion in 2021 to USD 726.73 billion by 2026, driven by emerging innovations like Ceramic Semiconductors. These materials boast enhanced temperature stability and improved electrical performance, making them ideal for a wide range of applications, including power electronics and high-frequency circuits. Their lightweight and compact nature further contributes to the miniaturization trends observed in modern electronics. As industries increasingly seek efficient and sustainable solutions, the integration of Ceramic Semiconductors is set to redefine performance standards and open new avenues for technological advancement.

Ceramic semiconductors are a groundbreaking innovation that stands out due to their unique composition and properties. Unlike traditional semiconductor materials such as silicon, ceramic semiconductors are made from inorganic compounds, which provide enhanced thermal stability and chemical resistance. This composition not only allows them to operate in extreme environments but also contributes to their durability, making them suitable for applications where conventional semiconductors might fail.

The structural integrity of ceramic materials is a key factor in their performance. They are primarily composed of metal oxides, nitrides, or carbides, which exhibit high dielectric strength and low electrical conductivity under certain conditions. This property is essential in designing devices that require high efficiencies and minimal power loss. Furthermore, the ability to tailor the composition of ceramic semiconductors means that researchers can fine-tune their properties to fit specific technological needs, paving the way for advancements in electronics, sensors, and power devices.

| Feature | Description | Advantages | Applications |

|---|---|---|---|

| High Thermal Stability | Ceramic semiconductors can operate at elevated temperatures without degradation. | Increased performance in extreme environments. | Aerospace, automotive electronics. |

| Electrical Insulation | Ceramic materials provide excellent insulating properties. | Minimized risk of electrical shorts. | Power electronics, high voltage applications. |

| Unique Composition | Made from a blend of metal oxides and other compounds. | Tailored properties for specific electronic requirements. | Sensors, capacitors, and transistors. |

| Environmental Resistance | Resistant to moisture, corrosion, and temperature fluctuations. | Longer lifespan and reliability in harsh conditions. | Telecommunications, industrial sensors. |

The emergence of ceramic semiconductors marks a transformative shift in the technology landscape, particularly when compared to traditional materials like silicon. According to a recent report from MarketsandMarkets, the global semiconductor market is projected to reach USD 1 trillion by 2030, with a significant portion of this growth attributed to innovative materials. Ceramic semiconductors are not only lighter and stronger but also offer higher thermal stability and resistance to chemical corrosion, making them ideal for high-performance applications in electronics, automotive, and aerospace industries.

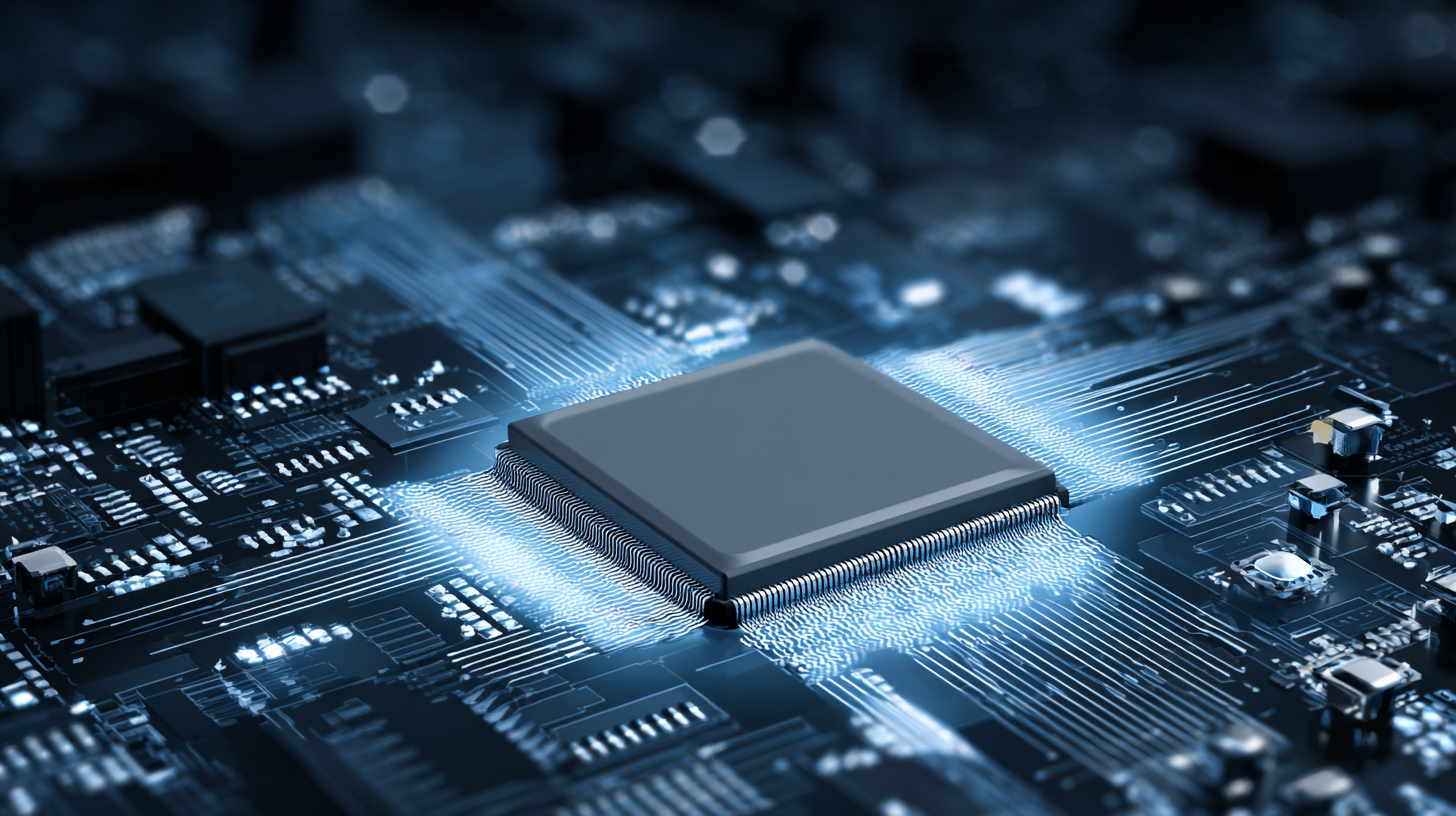

One of the standout advantages of ceramic semiconductors is their ability to operate effectively at elevated temperatures. Unlike silicon, which can degrade in high-temp environments, ceramic materials can withstand temperatures exceeding 1000°C. This characteristic opens doors to applications in extreme conditions, as highlighted by a study from the International Journal of Applied Ceramic Technology, which found that ceramic semiconductors exhibit a 50% higher operational lifespan under such stress. Additionally, their lower thermal expansion coefficient makes them less prone to mechanical failure.

**Tip:** When designing systems for high-temperature applications, consider integrating ceramic semiconductor materials to enhance durability and performance. Furthermore, their lightweight nature can contribute to overall energy efficiency in automotive and aerospace designs, leading to reduced emissions in line with growing sustainability goals. Embracing this innovation can not only improve product performance but also align with modern environmental standards.

Ceramic semiconductors represent a remarkable advancement in modern technology, showcasing their versatility across various applications. One prominent area is in electronic devices where their high thermal stability and excellent insulating properties enhance performance. These semiconductors can effectively manage heat in high-power applications, making them ideal for use in electric vehicles and renewable energy systems. Their ability to operate efficiently at elevated temperatures opens new possibilities for reliability and energy efficiency in diverse environments.

Another significant application lies in the realm of sensors. Ceramic semiconductors are increasingly utilized in sensor technology for automotive and industrial applications, where durability and resilience are crucial. Their unique composition allows for the detection of gases and environmental changes with precision, contributing to advancements in safety and environmental monitoring. As industries continue to evolve towards smarter and more sustainable technologies, ceramic semiconductors are poised to play a pivotal role in driving innovation forward, thereby enhancing both performance and longevity in various technological domains.

The manufacturing process of ceramic semiconductors presents both innovative opportunities and significant challenges. Advanced ceramics, including materials such as zirconia and silicon carbide, play a crucial role in this field due to their superior properties, including chemical stability and thermal resistance. According to recent market analysis, the advanced ceramics market is projected to grow significantly, driven by increasing demands in semiconductor production. The market size for advanced ceramics is categorized into various products, with significant shares held by alumina and silicon nitride, as they are essential for high-performance applications in electronics.

However, developing ceramic semiconductors also involves overcoming manufacturing challenges such as material compatibility and processing techniques. The adoption of automated processes is being explored to enhance efficiency and reduce human error, as highlighted in a study that discusses automation trends in semiconductor manufacturing. Furthermore, innovative solutions like MXene-based ceramic nanofiltration membranes are being investigated for their potential to selectively separate contaminants in semiconductor wastewater, addressing both manufacturing resilience and environmental concerns. As the semiconductor industry evolves, these innovations signify a step towards sustainable and efficient production practices.

The ceramic semiconductor technology is poised for significant advancements, driving the future of the electronics industry. With the market for ceramic substrates expected to expand, a recent report forecasts that by 2032, the ceramic substrate market will reach substantial figures, with considerable growth projected across various sectors including consumer electronics and aerospace. This aligns with overall trends in the semiconductor materials market, projected to grow from approximately $5.9429 billion in 2024 to $6.6413 billion by 2032, reflecting a steady increase in demand driven by innovation.

As industries gear towards AI and smarter technologies, forums like the CPCA Show Plus are critical in promoting dialogue around these innovations. The conference, scheduled for 2025, emphasizes the convergence of AI, semiconductor advancements, and ceramic technologies, showcasing how these elements will interact to shape the future landscape. Furthermore, the integration of emerging solutions, such as diamond microchannels for chip cooling, is an illustration of the cutting-edge developments that will redefine thermal management in semiconductor applications, ensuring efficiency and performance.