In the quest for enhanced durability and performance of steel materials, the application of **Ceramic Coating on Steel** has emerged as a transformative solution. According to a recent report by Markets and Markets, the global ceramic coatings market is expected to reach $13.5 billion by 2027, driven by the increasing demand for corrosion resistance and wear protection across various industries. This innovative technology not only improves the lifespan of steel components but also offers exceptional resistance to high temperatures and chemical exposure. With industries ranging from automotive to aerospace facing escalating operational challenges, leveraging the benefits of ceramic coatings has become essential. This blog will explore not only the advantages of ceramic coating but also effective techniques for application, ensuring that steel components can withstand the rigors of demanding environments while maintaining structural integrity.

Ceramic coatings are rapidly gaining popularity as a method to enhance the durability of steel in various applications, thanks to their remarkable benefits. These coatings provide an excellent barrier against corrosion and wear, significantly extending the lifespan of steel components in harsh environments. Recent advancements in eco-friendly materials have introduced epoxy nanocomposite coatings reinforced with innovative additives, such as chitosan-derived nitrogen-doped graphene, that enhance corrosion resistance and mechanical performance. Such developments represent a shift towards more sustainable and effective protective solutions for steel.

In addition to corrosion resistance, ceramic coatings also contribute to improved thermal stability and mechanical strength. Technologies like nanostructured thermal barrier coatings are essential for high-temperature applications, including gas turbines and aerospace engines, where traditional coatings may fail. Furthermore, multifunctional coatings exhibiting superhydrophobic properties provide long-term protection, allowing for self-cleaning and anti-fouling capabilities. The integration of these advanced ceramic-coating techniques demonstrates a significant leap forward in enhancing the durability and performance of steel, making it a crucial component in modern engineering and manufacturing.

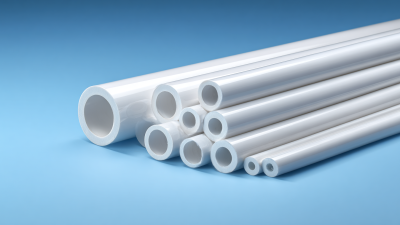

When it comes to enhancing the durability of steel, ceramic coatings stand out as an innovative solution. One of the key techniques for effective application is surface preparation, which plays a crucial role in the adhesion and longevity of the coating. Proper cleaning and surface profiling ensure that any contaminants, such as oils, dust, or oxidation, are removed. This can involve mechanical abrasion or chemical cleaning, followed by a thorough rinse and drying process to achieve a smooth, optimal substrate.

Another essential technique is the correct application method, which may vary depending on the type of ceramic material used. Techniques like spraying, dipping, or brushing can be used, but spraying is often preferred for its even distribution and ability to cover complex geometries. It’s also important to control the application environment, ensuring that temperature and humidity levels are ideal for curing the coating effectively. By paying attention to these details, the final product not only exhibits improved resistance to abrasion and corrosion but also maintains its aesthetic appeal over time.

In recent years, the trend of enhancing steel durability through advanced treatment methods has gained significant traction, with ceramic coating emerging as a forefront contender. Comparing ceramic coating to traditional steel treatments reveals distinct advantages that can influence decision-making in various industries. Traditional methods, such as galvanization or painting, often provide a basic level of protection but may not stand up to harsh environmental conditions or wear over time. These treatments can chip or degrade, leading to the re-exposure of the steel beneath.

On the other hand, ceramic coatings are engineered to create a robust barrier that not only resists corrosion and abrasion but also improves overall aesthetic appeal. Their unique properties allow for better heat resistance and lower friction, making them ideal for applications in automotive, aerospace, and industrial sectors. Additionally, ceramic coatings can be tailored to meet specific requirements, enhancing their compatibility with different steel types. Ultimately, the comparative analysis highlights that while traditional treatments have their place, the superior durability and versatility of ceramic coatings make them an attractive option for those seeking long-lasting performance and protection for steel products.

To maximize the lifespan of coated steel, regular maintenance is crucial. One of the primary benefits of ceramic coatings is their ability to resist corrosion and wear, but over time, even the best coatings can degrade without proper care. According to a recent report by the National Association of Corrosion Engineers (NACE), maintenance practices can improve the longevity of coated steel by up to 30%. Routine inspections should be conducted to identify any signs of wear or damage, allowing for timely repairs that can restore the coating's protective properties.

Cleaning is another vital aspect of maintaining coated steel. Industry standards recommend using non-abrasive cleaning agents to avoid damaging the ceramic layer. For example, the Society for Protective Coatings (SSPC) suggests using a soft brush or cloth along with mild detergent and water to keep the surface free of contaminants. Additionally, applying a sealing treatment every couple of years can enhance the durability of the coating, further extending the lifespan of the underlying steel. By following these maintenance tips, one can significantly enhance the performance and longevity of ceramic-coated steel structures.

When applying ceramic coatings to steel surfaces, several common mistakes can undermine the benefits of this advanced technology. One significant error is inadequate surface preparation. According to a report from the Coating Society, improper cleaning or insufficient surface roughness can lead to poor adhesion, ultimately reducing the coating's effectiveness. Steel surfaces should be meticulously cleaned and pre-treated to remove any contaminants, ensuring the ceramic layer bonds properly and lasts longer.

Another critical mistake is neglecting the application environment. Environmental factors, such as humidity and temperature, play a vital role in the curing process of ceramic coatings. A study published in the Journal of Materials Science indicates that applying coatings in extreme conditions can lead to defects like blistering or peeling. Maintaining a controlled environment can help achieve optimal results and enhance the durability of coated steel. Moreover, it's essential to follow the manufacturer's guidelines on curing times and thickness; deviations can severely impact the coating’s performance and longevity.

| Technique | Benefit | Common Mistake | Resolution |

|---|---|---|---|

| Thermal Spraying | Increases resistance to wear and heat | Insufficient surface preparation | Thoroughly clean and roughen the surface |

| Dip Coating | Provides uniform coat thickness | Incorrect temperature control | Monitor and adjust the dipping temperature |

| Powder Coating | Enhances corrosion resistance | Over-curing the coating | Follow the manufacturer's curing schedule precisely |

| Chemical Vapor Deposition | Produces high-quality, durable coatings | Inappropriate gas mixture | Ensure correct gas ratios and conditions |