Products

Silicon Carbide: The Future of High-Performance Materials

Silicon carbide (SiC) is a structural ceramic material with excellent properties. Silicon carbide parts, that is, equipment parts with silicon carbide and its composite materials as the main materials, have the characteristics of high density, high thermal conductivity, high bending strength, large elastic modulus, etc., and can adapt to the harsh reaction environment of strong corrosiveness and ultra-high temperature in wafer epitaxy, etching and other manufacturing links, so it is widely used in major semiconductor equipment such as epitaxial growth equipment, etching equipment, oxidation/diffusion/annealing equipment.

High-Quality Aluminum Oxide: Ideal for Industrial Applications

① Aluminum oxide is an important type of oxide ceramic, widely used in precision components of semiconductor equipment, wafer polishing processes, aerospace fields, automotive industry, and medical device industry, etc.

② Depending on the crystal structure, aluminum oxide can be divided into α-alumina, β-alumina, γ-alumina, and δ-alumina.

③ Currently, the purity of aluminum oxide ceramics on the market generally includes 95%, 99%, 99.5%, 99.7%, 99.9%, and 99.99%. For example, the highest purity aluminum oxide ceramic targets are used in the preparation process of semiconductor integrated circuit chips.

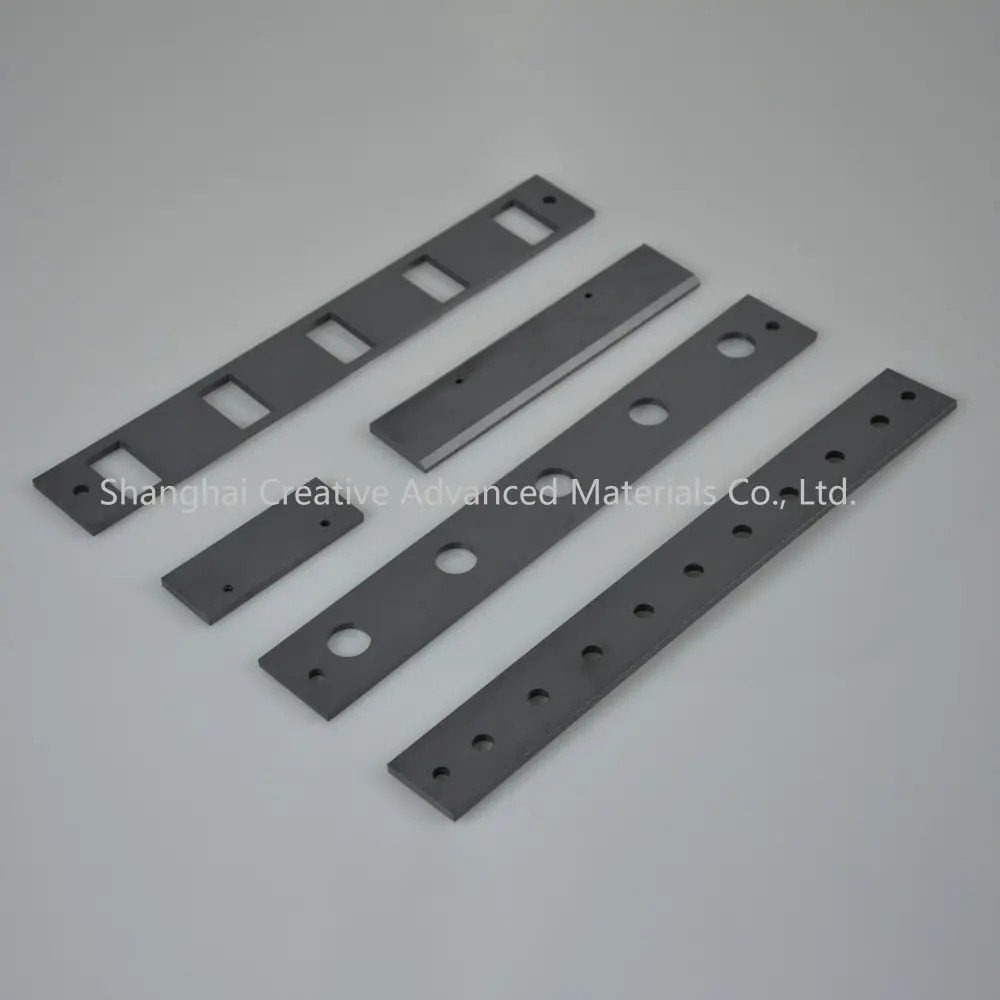

High-Performance Boron Carbide for Industrial Applications

① Boron carbide ceramic is a ceramic material composed of carbon and boron elements. It has many unique properties that make it widely used in various fields.

② In the civilian field, boron carbide ceramic is commonly used in engineering ceramics and wear-resistant technology, making boron carbide ceramic products such as boron carbide nozzles widely used in daily life and in industrial and agricultural production.

③ In the nuclear industry, boron carbide's excellent thermal neutron absorption capability makes it a control rod, regulating rod, accident rod, safety rod, shielding rod, and is used in the production of boron carbide tiles and plates for radiation protection.

④ In the military field, boron carbide ceramic is widely used in bulletproof vests, bulletproof armor, armed helicopters, and special vehicles for police and civilian use, making it the best material for bulletproof vests, helmets, and armor.

Boron Nitride: Versatile Material for Industrial Use

Boron nitride ceramic is a new type of inorganic non-metal material with a flaky structure, obtained by hot pressing sintering of boron nitride and composite material powders, and it possesses special physical and chemical properties as a hexagonal crystal system. Due to the high-temperature and high-pressure sintering of boron nitride powder, its appearance is white, commonly known as "white graphite". Boron nitride can maintain its structural integrity and mechanical properties under extreme high-temperature conditions. Boron nitride can resist oxidation up to 900°C in the air, and its sintering temperature can reach 2000°C under vacuum conditions.It can be used as crucibles, boats, and liquid metal transportation pipes for melting and evaporating metals, rocket nozzles, and bases for high-power devices. It is widely used in electronic packaging and thermal management materials, such as thermal interface materials, insulating ceramics, and high-frequency electronic components.

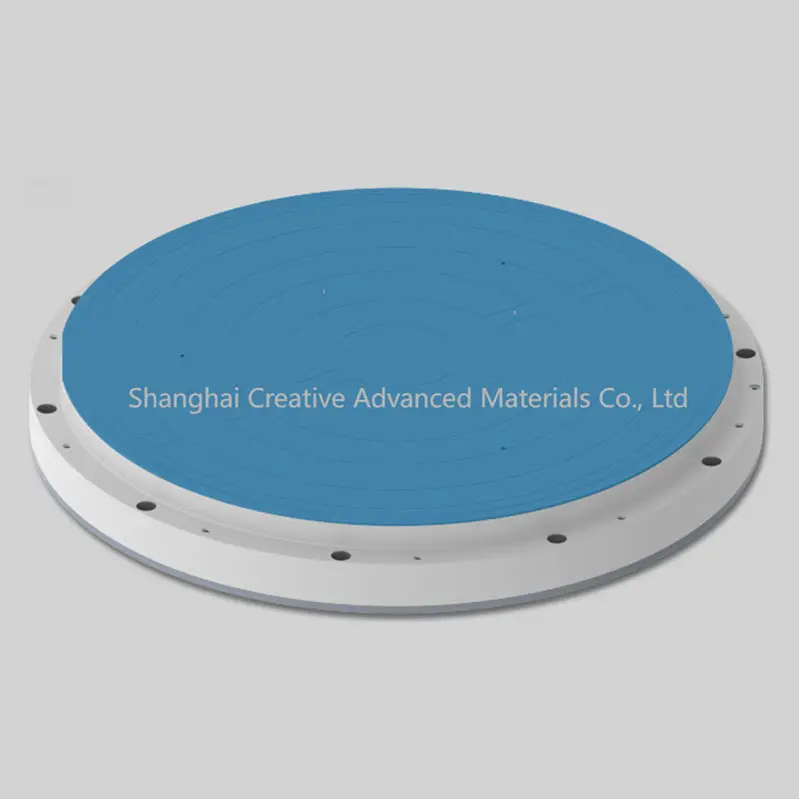

Premium Al2O3 Ceramic Components for Enhanced Performance

Alumina ceramics are special ceramics made of Al2O3 as the main raw material, rare metal oxides as fluxes, and roasted at a high temperature of more than 1,000 degrees. The product has the characteristics of wear resistance, corrosion resistance, heat resistance, impact resistance, high hardness, high voltage resistance, insulation and heat conductivity.

Iron Cobalt Tantalum alloy FeCoTa

Iron-cobalt-tantalum alloy is an alloy composed of iron, cobalt and tantalum, the target shape is usually round, and the deposition of the film layer is an important soft magnetic layer material for vertical magnetic recording medium. Since the alloy material contains a large amount of tantalum, segregation will occur during the solidification process, which does not help to deposit a film with uniform composition, and we use a unique fast cooling process to obtain an alloy target with fine grains and uniform composition. In order to ensure the purity of the material and reduce the number of inclusions, the high-purity stable crucible and high-vacuum melting technology are adopted to ensure the purity of the material, improve the mechanical properties of the material, and avoid the cracking of the target during use.

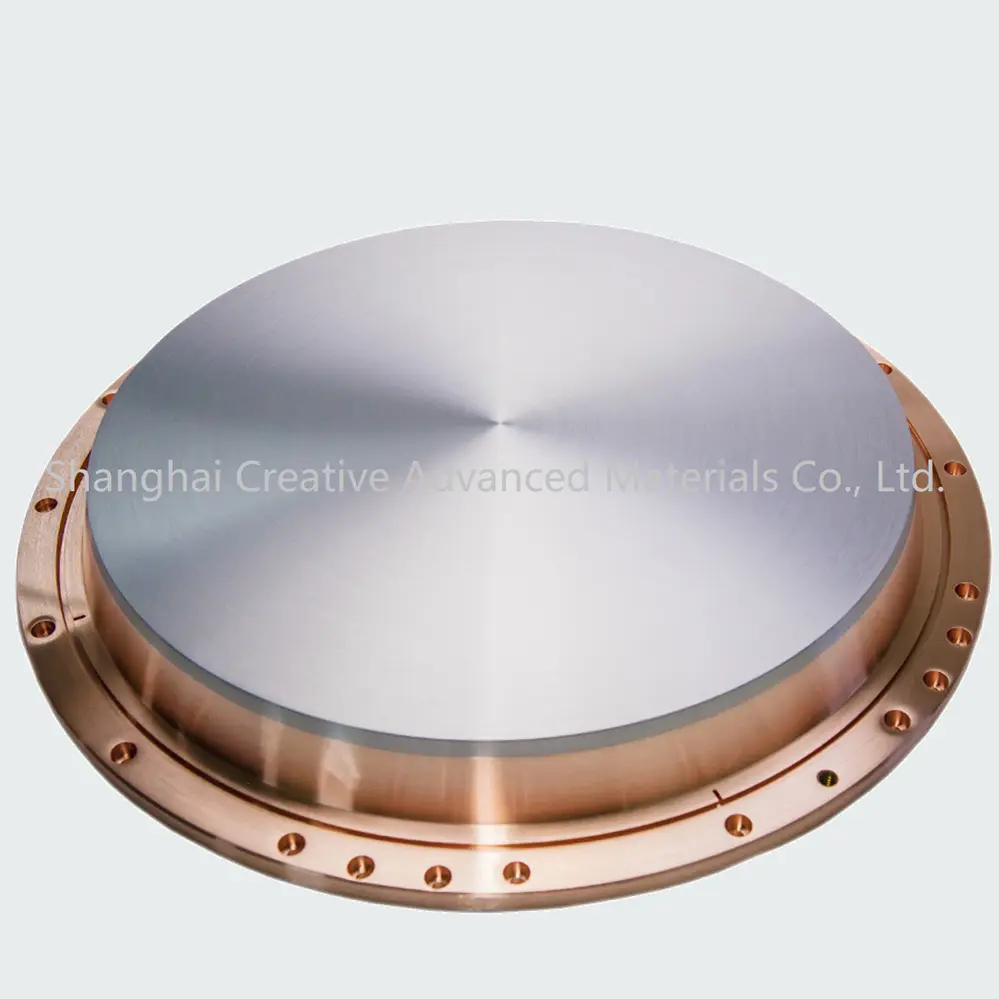

Reliable 300mm WSi Target for Enhanced Performance

W–Si alloy blocks were prepared by vacuum calcination, using the W and Si mixed powders as the raw materials, and the W–Si sputtering targets followed the requirements of semiconductor application were successfully prepared by crushing and sintering. The influence of calcination temperature and holding time on the phase composition, microstructure, oxygen content, and carbon content (mass fraction) of the alloyed block was investigated. The results indicate that the oxygen content and carbon content can be remarkably reduced by high temperature calcination process. In addition, the calcination temperature has an important effect on the removal of oxygen. The optimal preparation process is the calcination at 1250 ℃ for 5 h. Under this condition, the mass fraction of oxygen in the material can be reduced from 0.3000% to 0.0121%, and the elemental tungsten phase in the material is completely transformed into the tungsten−silicon alloy phase.

High-purity tungsten target 300mm W Target

High-purity tungsten target refers to the material with tungsten purity of 99.999% or more in the target. It is mainly prepared by high-purity tungsten powder pressed blank by hot rolling after high-temperature sintering. It has the properties of high purity, high density, high melting point, low resistance, good elasticity, low expansion coefficient, small vapor pressure, strong deflection strength, and good thermochemical stability.

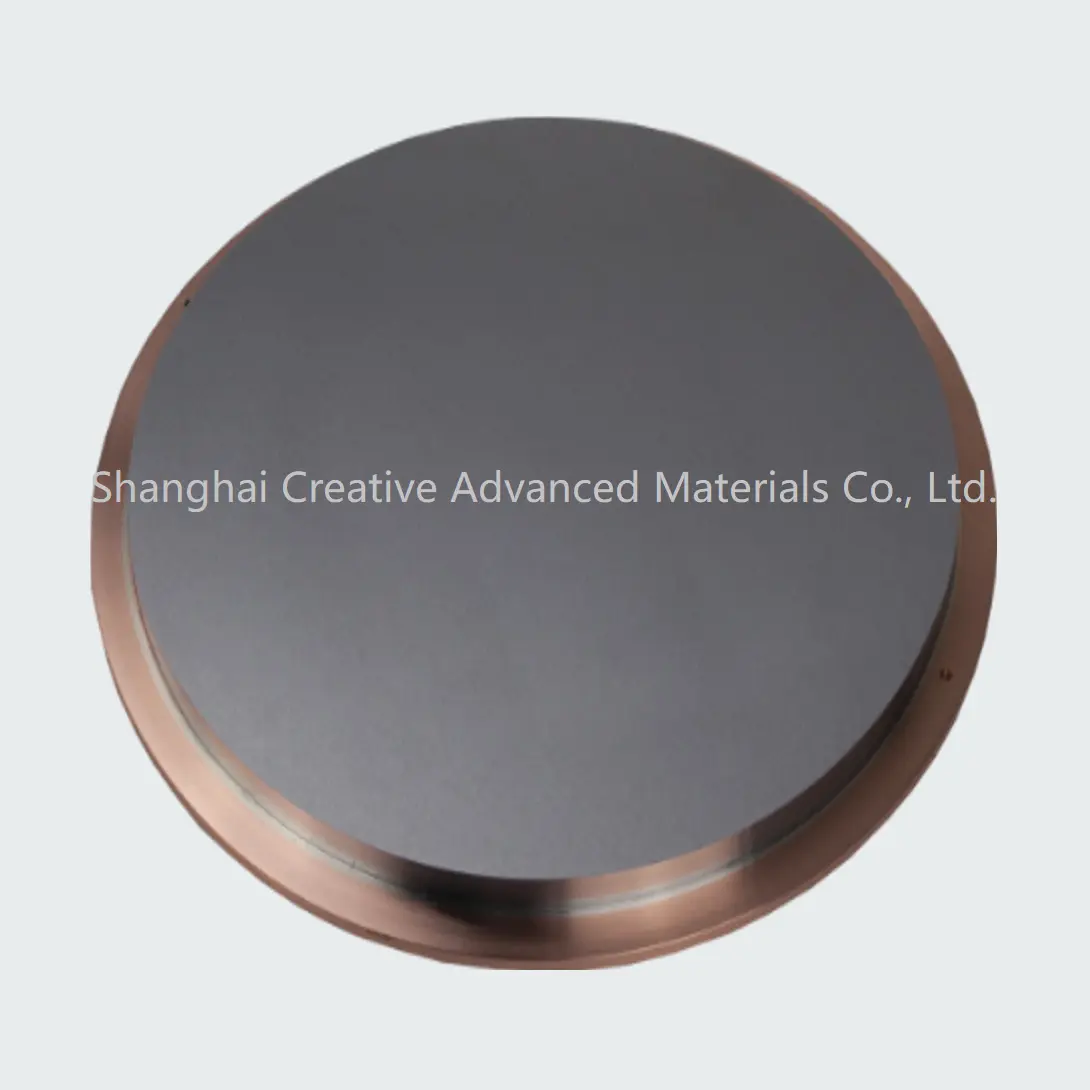

High-Quality 300mm Cr Target for Precision Applications

Chromium targets have the same properties as chromium metal (Cr). Chromium target is a steel-gray, shiny, hard, and brittle transition metal. In a vacuum, chromium targets can produce relatively stable chromium ion beams, which allows them to be used to make substrates or surface coatings to protect substrates or to make industrial parts that require high oxidation resistance. Chromium targets can also be used to prepare stoichiometric studies of chromium compounds.

Premium B4C Powder for Industrial Use and Research

Boron carbide has been widely used as a new material with excellent mechanical properties, irradiation self-resettable properties and neutron absorption ability. Since the first successful synthesis of boron carbide in the early 20th century, in the past 100 years, with the development of technology, the synthesis technology of boron carbide has not only been limited to the original element synthesis method, but also with the selection of raw materials, sintering process, reaction time and other technologies, the preparation methods of boron carbide powder have been diverse.

Ti3O5 Slug

Ti3O5 Slug uses advanced language processing technology, allowing it to generate natural-sounding, coherent text suitable for a variety of uses. Whether you need blog posts, articles, product descriptions, or any other type of written content, this tool has you covered.

Tungsten titanium alloy target 300mm Wti Target

Tungsten titanium alloy target is produced by powder metallurgy technology, tungsten titanium alloy is an alloy material with the advantages of both transition metal tungsten and titanium. It has the characteristics of higher density and purity, better corrosion resistance, and less volumetric expansion effect, which can effectively reduce the formation of particles in the manufacturing process, that is, it can successfully prepare high-quality products. According to the different purposes of use, there are different requirements for the impurity content of high-purity tungsten target and tungsten titanium target, and the chemical purity is generally required to be between 99.99%~99.999%, and we can also customize other specifications suitable for the application according to user requirements.